ANTZ SCM

Smart Warehouse Distribution

RFID Warehouse Management

System

in Malaysia

An RFID warehouse management system in Malaysia that’s not only reducing the dependencies on manpower but also eliminates unnecessary operation losses owing to human mistakes. With accurate inventories come greater planning and mobilisation of stock and cash flow.

1

Radio Frequency Identification in Warehouse Operations

2

Implementation of RFID in Warehouse Management System

Inventory Tracking

Read more: Inventory System in Malaysia.

Safeguarding of Goods

Picking and Packing

Receiving and Stowing

- The smart RFID forklift or reach-truck terminal automatically suggests and updates the placement location of goods, to reflect a highly reliable storage location of inventories.

- The Passive RFID RTLS or Real Time Location System is another cutting-edge RFID technology that facilitates a granular tracking of goods movement in 3-axis positioning.

Movement of Goods

3

Benefits of RFID Technology in Warehouse Management System

Improve Inventory Visibility

Reduce Overstocking and Understocking

Better Productivity and Insights

Read more about how RFID technology can enhance your warehouse management: 7 Benefits of RFID Technology in Warehouse Management Systems.

Inventory Tracking

Safeguarding of Goods

Picking and Packing

Receiving and Stowing

- The smart RFID forklift or reach-truck terminal automatically suggests and updates the placement location of goods, to reflect a highly reliable storage location of inventories.

- The Passive RFID RTLS or Real Time Location System is another cutting-edge RFID technology that facilitates a granular tracking of goods movement in 3-axis positioning.

Movement of Goods

Improve Inventory Visibility

Reduce Overstocking and Understocking

Better Productivity and Insights

Frequently Asked Questions on

RFID Warehouse

What are the disadvantages of RFID?

The price of an RFID tag is still relatively high compared to a traditional barcode label. Nonetheless, an RFID system outperforms a barcode system significantly.

Another disadvantage lies in the two biggest enemies of radio waves, metal and water. At ultrahigh frequencies, metal will deflect the radio signals transmitted and further interfere with the signal sent, whereas water absorbs the radio signals and weakens the signals.

Hence, it is always important to take these into consideration when implementing RFID warehouse management solutions, or even easier, get an RFID expert to advise on the implementation.

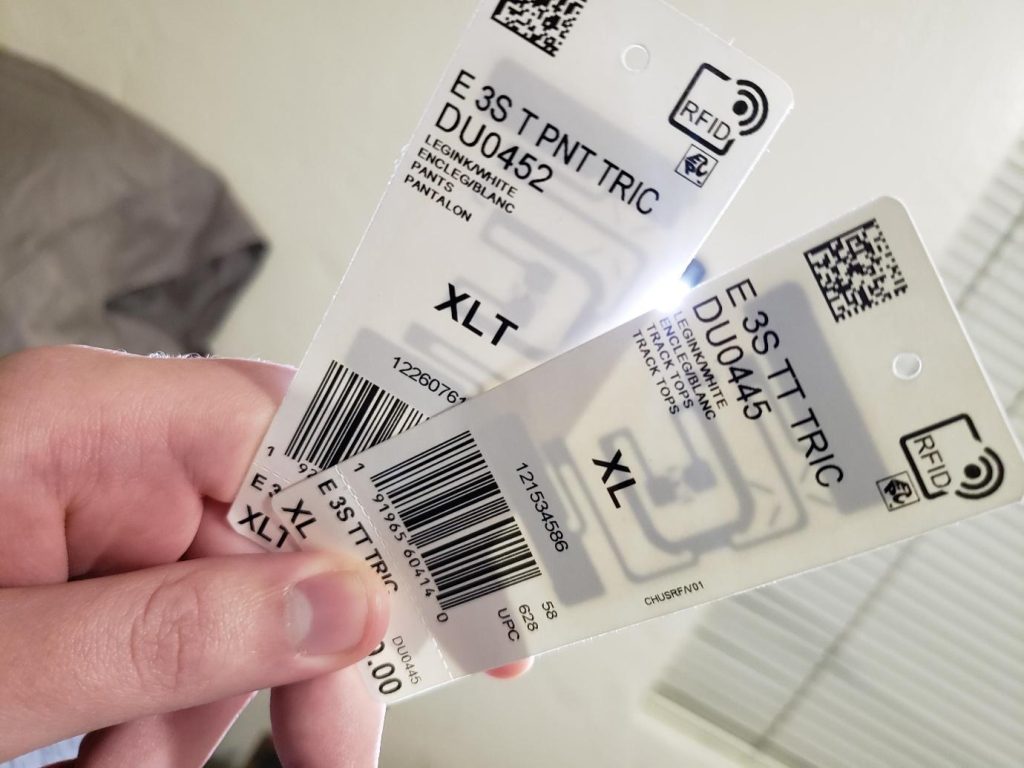

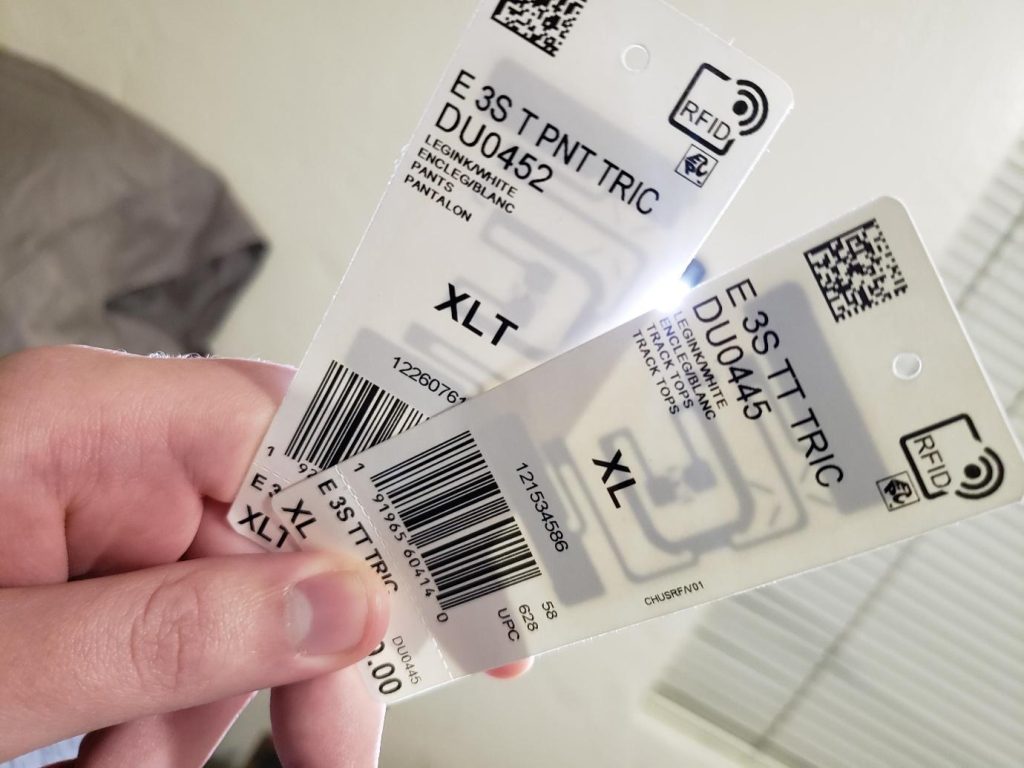

Is RFID better than a barcode?

Barcode scanners require direct line-of-sight to a product or item’s barcode in order for them to be read successfully, and as such can be extremely inefficient when dealing with hundreds or thousands of products in the entire pallet at once.

RFID on the other hand uses radio waves to penetrate surfaces and scan multiple items at once from any angle thanks to its penetrative nature. This makes the speed of RFID readers easily 500 times faster than barcode scanners can achieve.

Where is RFID data stored?

RFID data is primarily stored within the RFID IC or Integrated Circuit, which is a tiny chip embedded with an antenna made out of metal coils, allowing information to be read from it. RFID data can also be stored in a system database or warehouse management software.

What is the difference between GPS and RFID?

GPS is an electric-powered tracking system that provides the location of an object by reference to multiple satellites’ locating signals. It’s generally used for outdoor location-tracking applications.

RFID is meant for both location-tracking and process-tracking applications. It derives ‘what, when, where, who and how’ that answers the business needs. RFID is self-sustaining without requiring an external power source hence the maintenance of an RFID tag is negligible.

How far can RFID be tracked?

There are generally three main categories of RFID technologies, being differentiated by their operating frequency, namely the LF or Low Frequency, HF or High Frequency, and UHF or Ultra-High Frequency.

At Inchz IoT, we mainly focus on UHF RFID a.k.a. RAIN RFID which has a long range and simultaneous scanning capabilities. UHF RFID is able to reach out of a max range of 30 metres between the reader and the tag and is able to read a mass amount of tags at one time.